-

Renewables-based hydrogen produced via electrolysis will be crucial in making several no-regret applications climate-neutral.

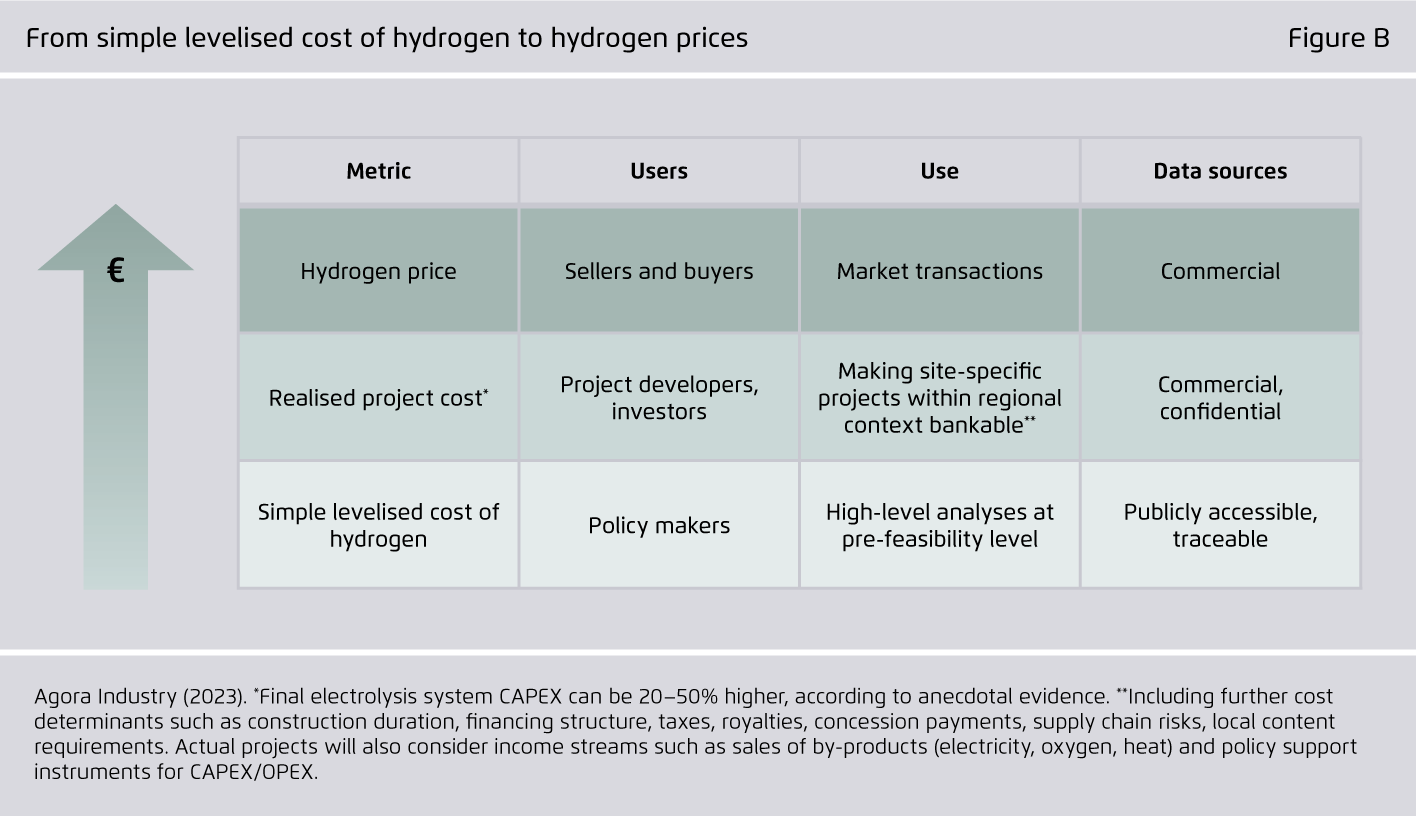

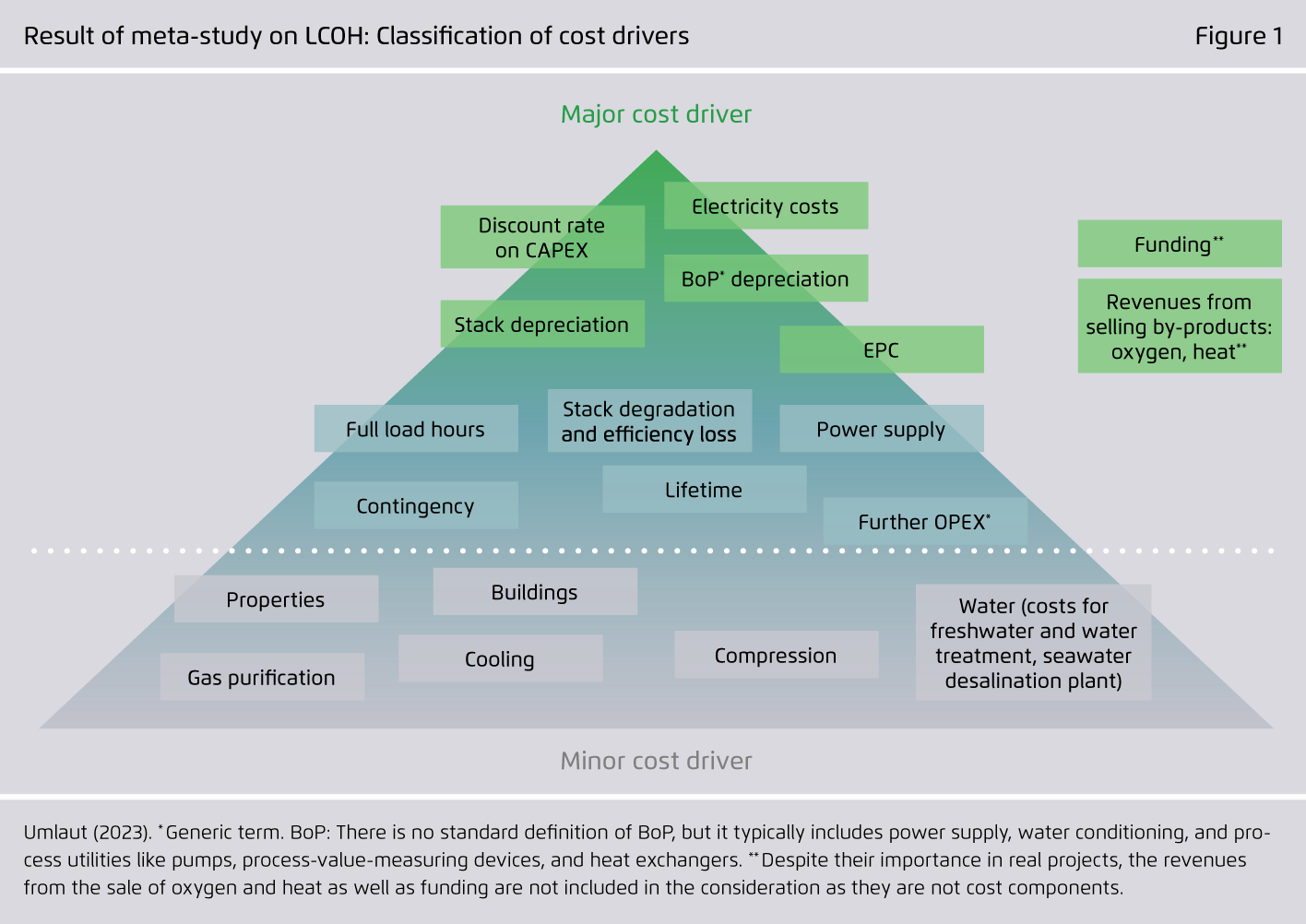

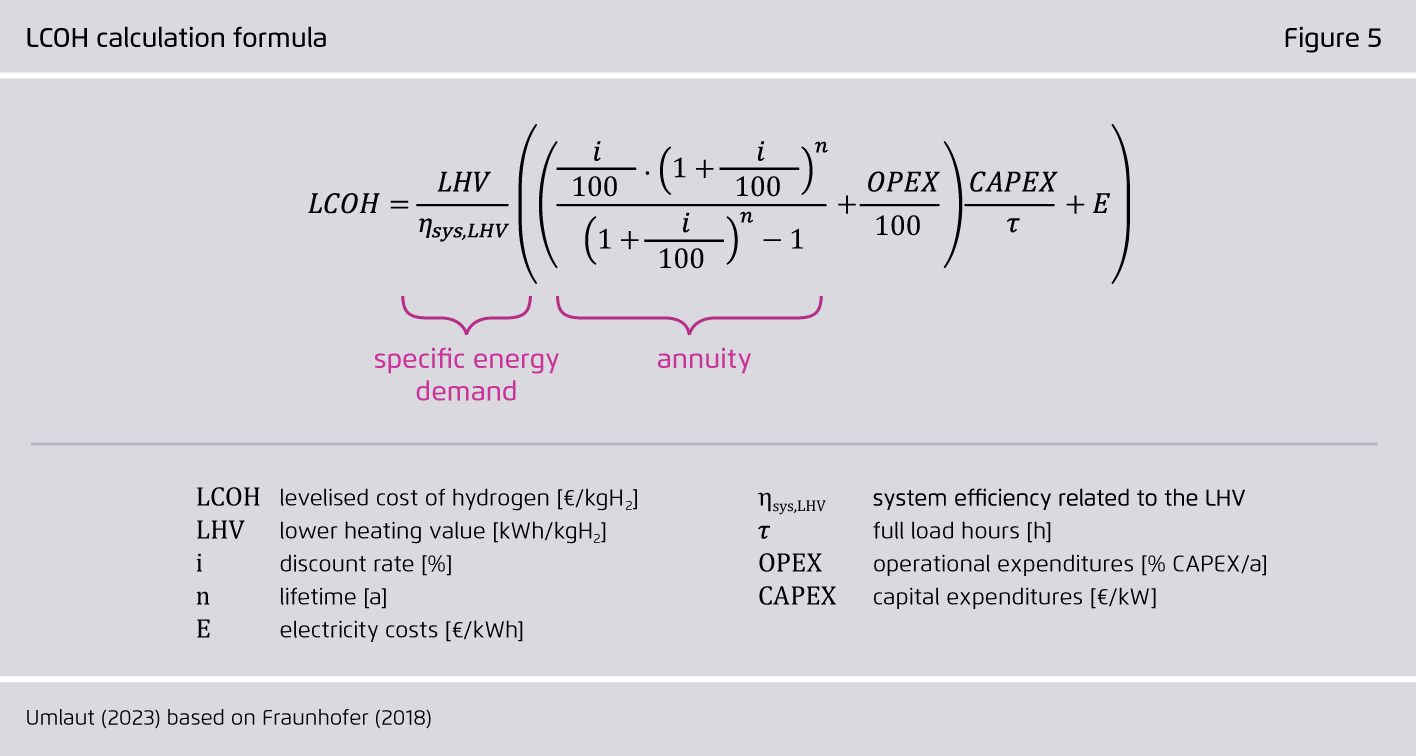

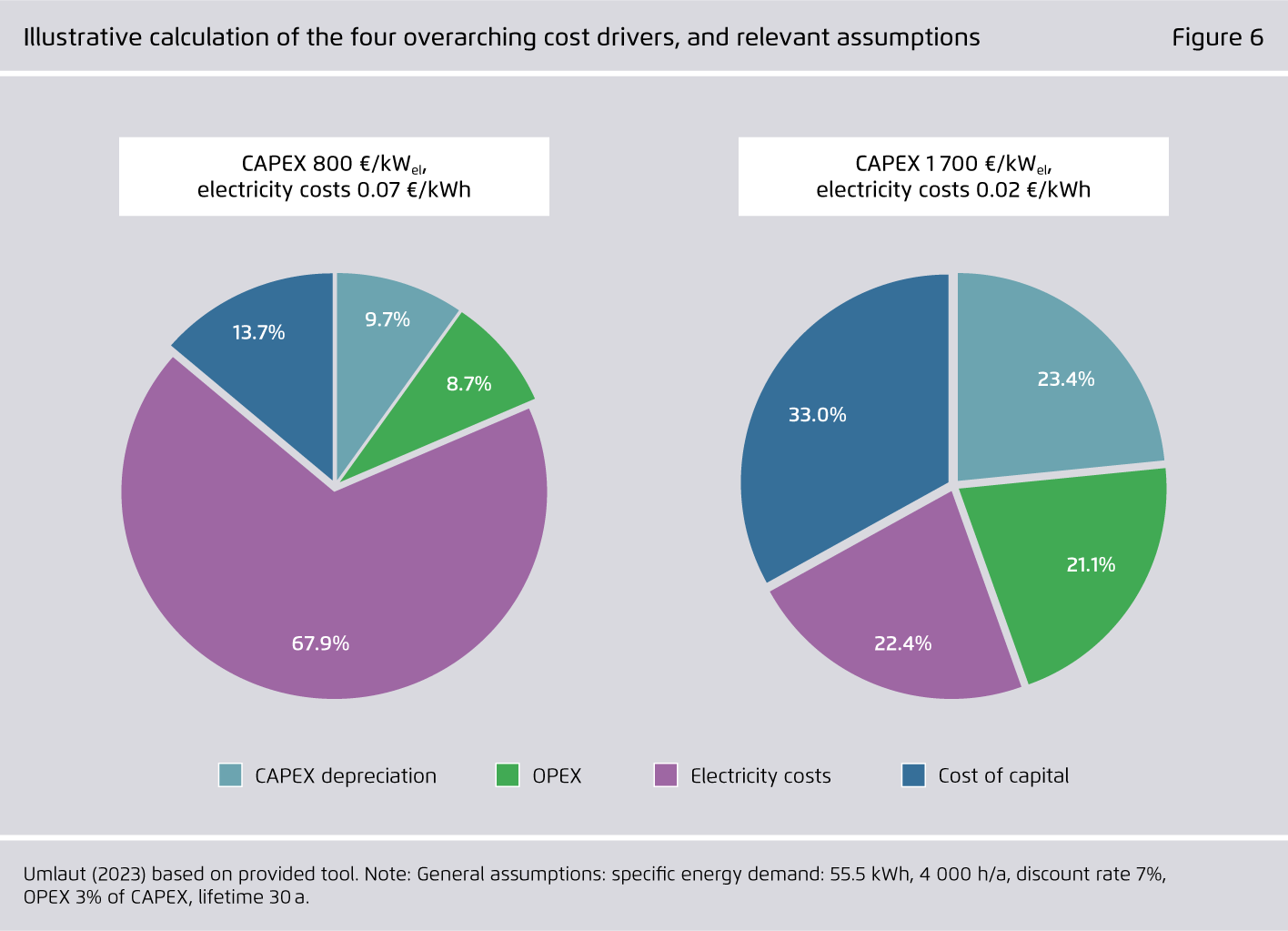

As long as green hydrogen requires public support to be economically competitive, policymakers need transparent estimates of the levelised cost of hydrogen to guide them in designing support schemes. Key drivers are the assumed electricity costs, the number of full-load hours, the cost of capital and the investment costs for electrolysers.

-

Optimal energy system integration leads to fewer full-load hours, increasing the proportion of capital expenditure in the overall cost of green hydrogen production.

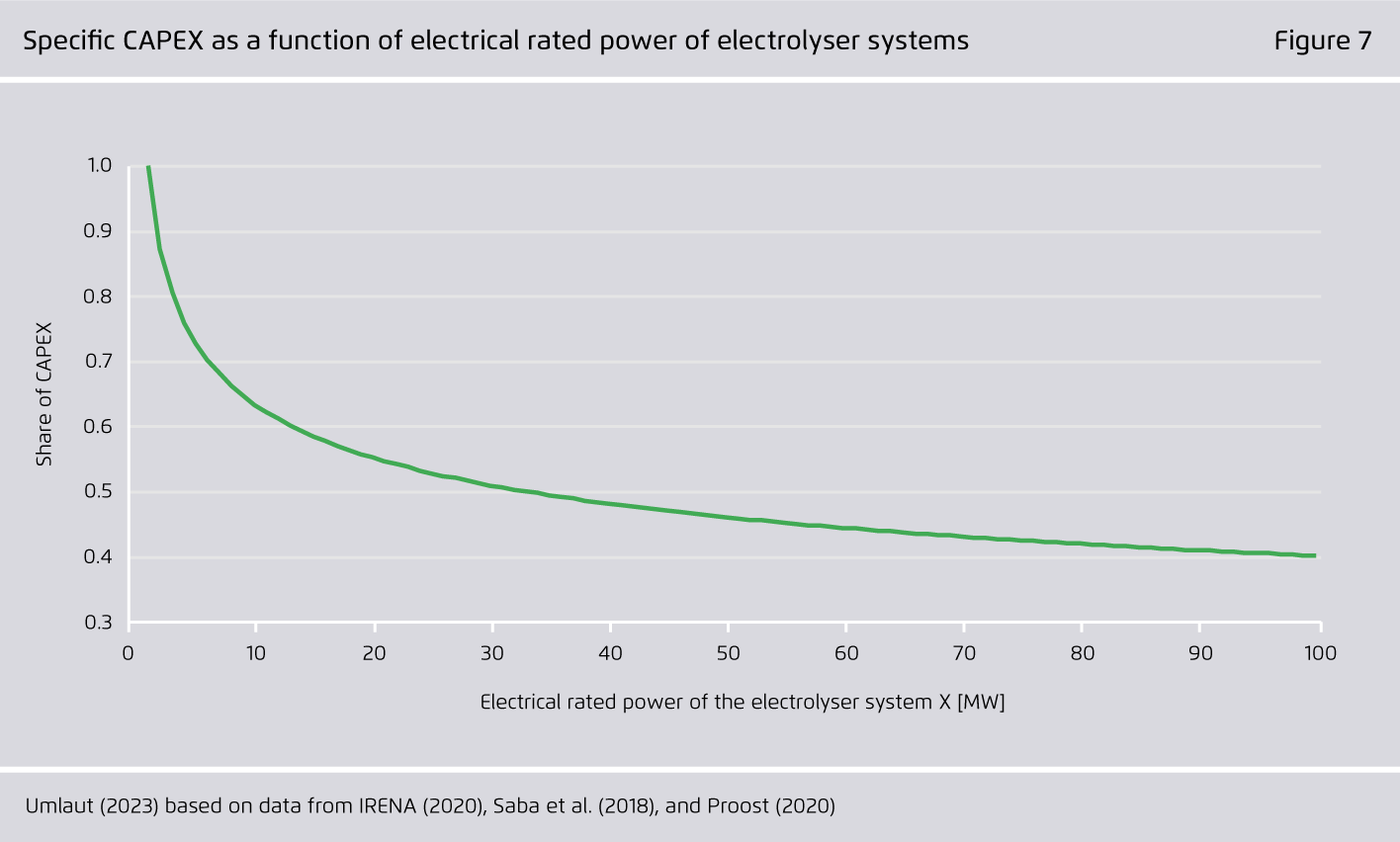

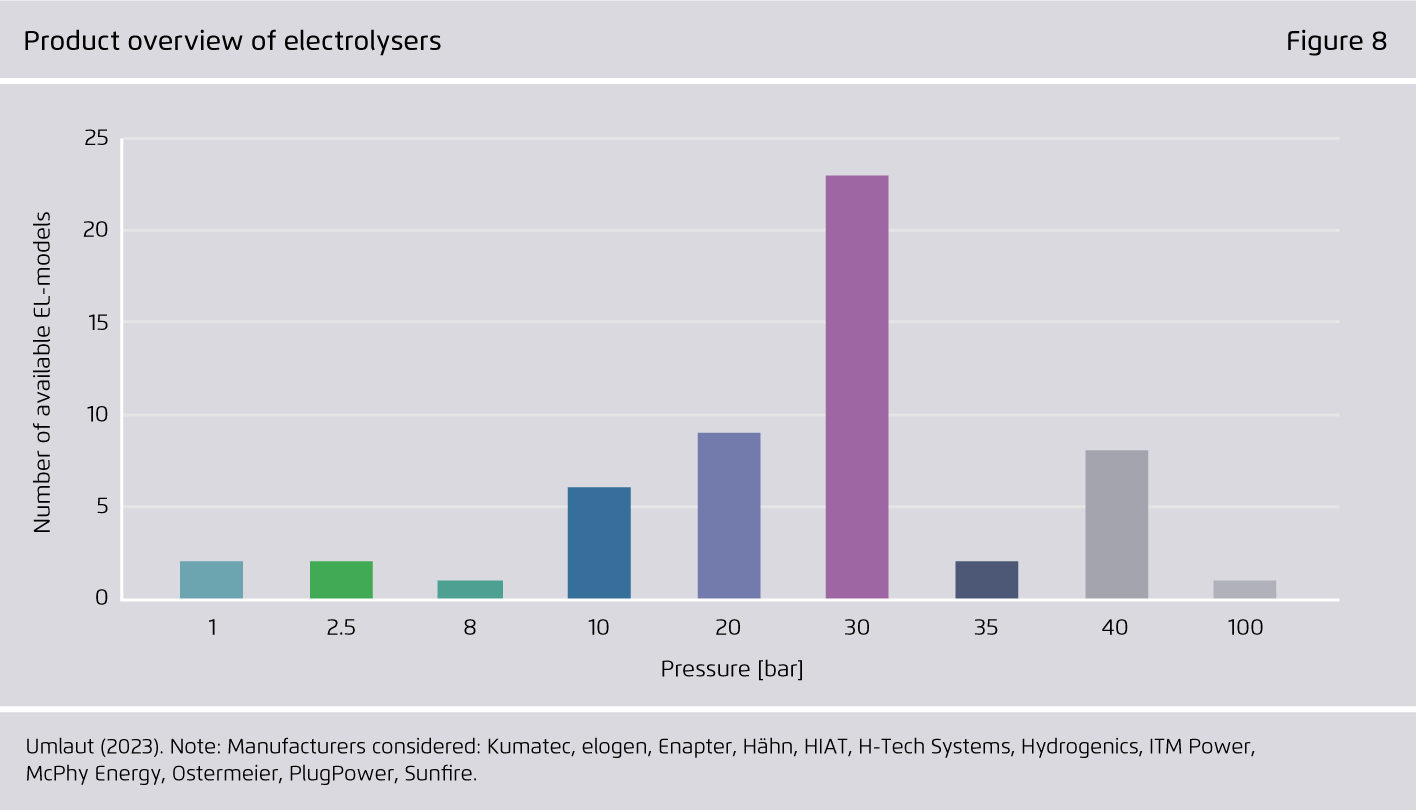

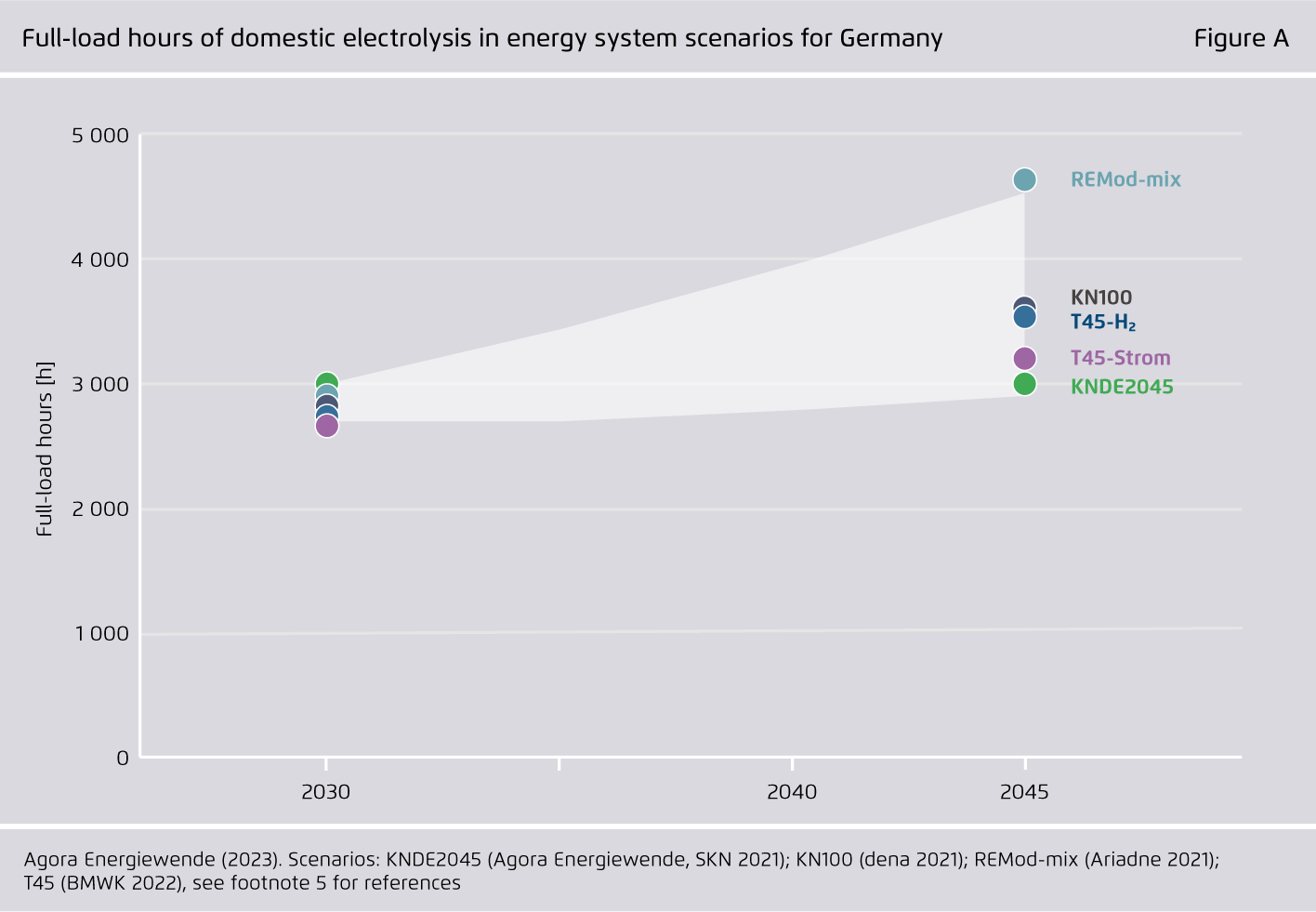

For example, most widely-cited German energy scenarios expect electrolysers to run ~3 000 full-load hours in 2030, corresponding to a ~34 percent utilisation rate, which is expected to gradually increase up to 2045. The lower the number of full-load hours, the greater the proportional significance of electrolysis investment costs becomes.

-

High-level guidance for policymakers based on simplified levelised cost calculations tends to

underestimate real-world project implementation costs and needs to be clear about these limitations.

The price for electrolyser systems in the EU today is still generally high (significantly above 1 000 Euro/kW), although it is projected to fall considerably in the future.

-

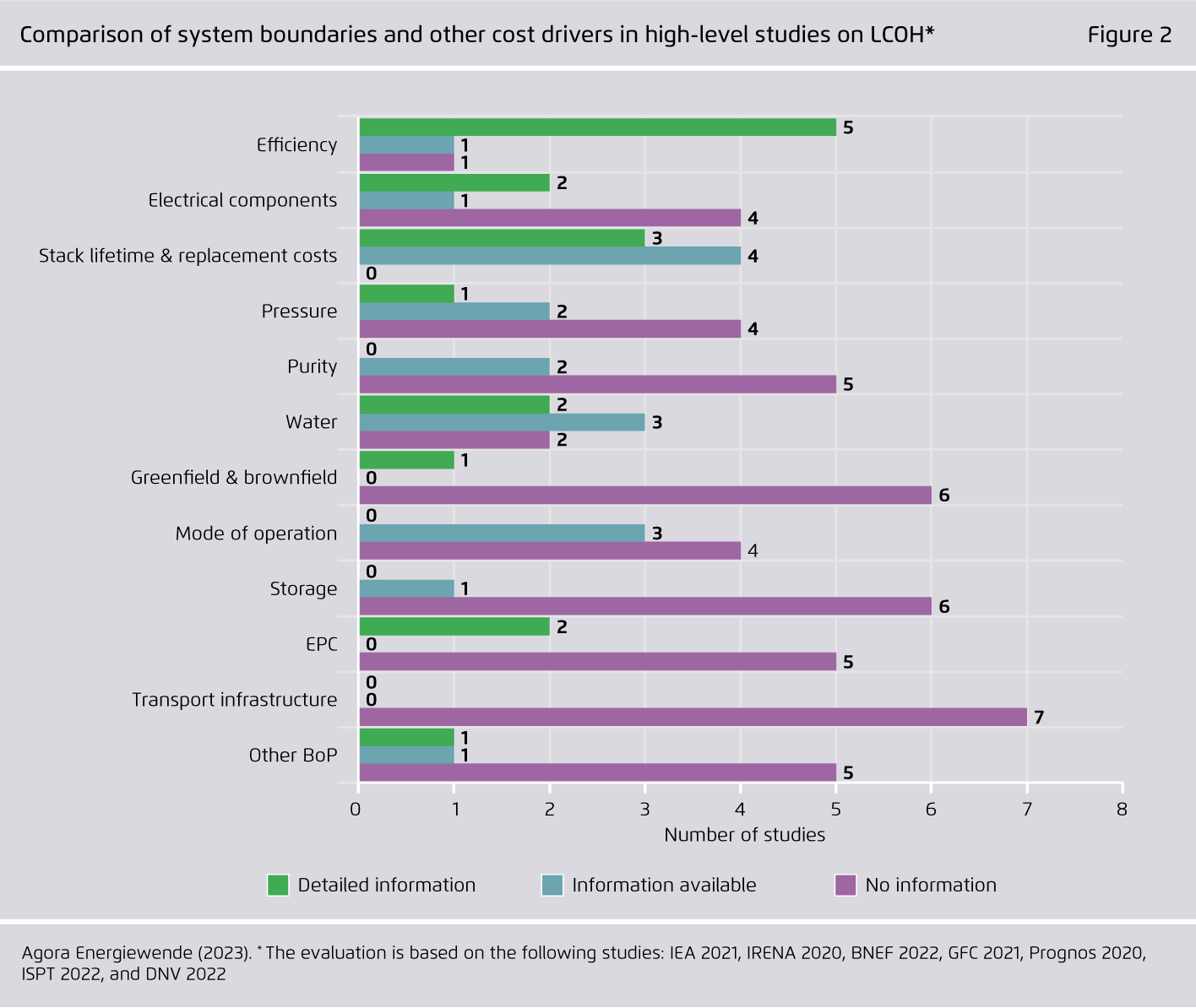

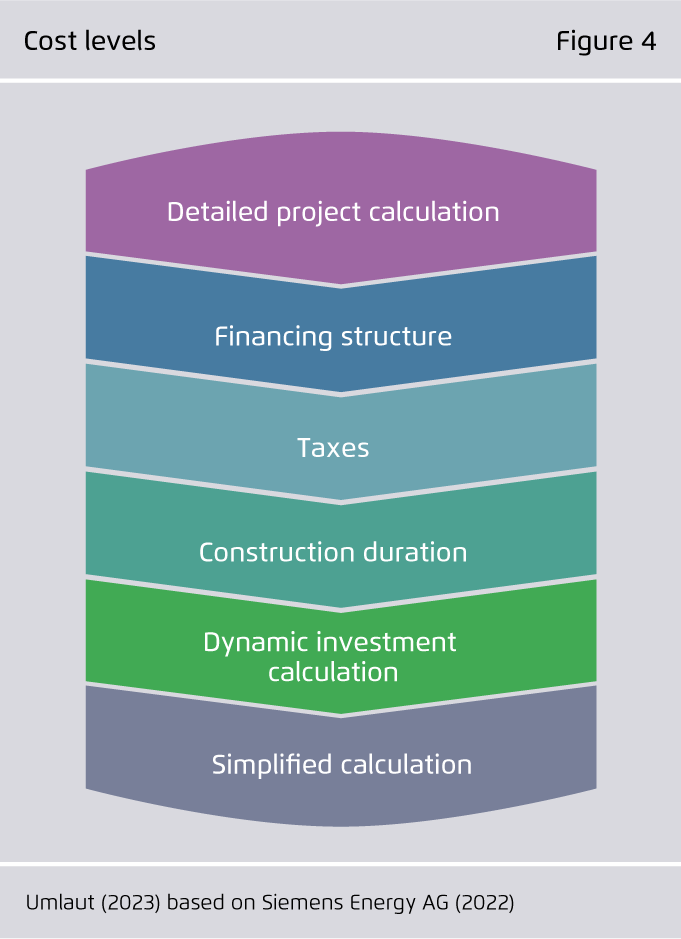

A pragmatic approach to cost calculations should focus on detailed fundamental cost drivers within generalised system boundaries while leaving out project- and site-specific considerations.

Other potentially important but non-fundamental cost drivers, such as project financing or tax credits, should generally not be factored in unless explicitly included. While simplified cost estimates are appropriate for high-level studies, their practicality depends on a sufficient degree of consistency and transparency regarding system boundaries and cost drivers.

Levelised cost of hydrogen

Making the application of the LCOH concept more consistent and more useful

Preface

The EU is raising its ambition for renewables-based hydrogen, and the regulatory framework required is taking shape. A long pipeline of green hydrogen projects awaiting final investment decisions can finally be opened. Meanwhile, China keeps increasing its cost advantage in electrolyser manufacturing, and the US Inflation Reduction Act, which includes a highly competitive package of incentives for hydrogen production in North America, has significantly increased the pressure on the EU. Against this background, the EU is intensifying efforts to develop production support schemes for renewables-based hydrogen in the context of the new Hydrogen Bank it has announced.

Numerous studies are now published every month containing estimates for the levelised cost of hydrogen (LCOH) production. They provide policymakers with the techno-economic basis on which to make their decisions and to design appropriate support schemes. But are the costs calculated consistently across these studies? How are system boundaries drawn? Which cost drivers are important, and which can be omitted?

This publication sheds light on why the LCOH differs both between individual studies and between studies and real-world projects and provides recommendations for improving the application of the concept based on sensible simplifications that enable LCOH comparisons.

Key findings

Bibliographical data

Downloads

-

Impulse

pdf 1 MB

Levelised cost of hydrogen

Making the application of the LCOH concept more consistent and more useful

-

Excel Tool

Levelised Cost of Hydrogen Calculator

The LCOH calculator is an interactive Excel tool that calculates simple levelised cost of hydrogen.

All figures in this publication

Full-load hours of domestic electrolysis in energy system scenarios for Germany

Figure A from Levelised cost of hydrogen on page 6

From simple levelised cost of hydrogen to hydrogen prices

Figure B from Levelised cost of hydrogen on page 7